Background

In the era of accelerated digital transformation, servers, as the core of information technology infrastructure, carry the data processing and storage needs of enterprises. With the rise of technologies such as cloud computing, big data and artificial intelligence, the server market is experiencing unprecedented growth opportunities. However, in the face of increasing performance requirements and increasingly complex assembly processes, enterprises urgently need to improve production efficiency and product quality. We provide innovative solutions for the server sector of the 3C industry, optimizing assembly and testing processes through intelligent technology to meet the market’s urgent demand for efficient and reliable servers and help enterprises stay ahead of the fierce competition.

Mac Mini Film and pressure retention

The Mac Mini’s film and pressure holding features include high precision application of a protective film to the surface of the device to prevent scratches and dirt, as well as effective pressure holding treatment to ensure a tight fit between the film and the body. This feature not only enhances the aesthetic appearance, but also enhances the durability of the device, providing an additional layer of protection to help users keep their Mac Mini in good condition, thus extending its service life.

Underlying Parameter

| Working pressure (M Pa) | 0.5~0.6mpa |

| Size(mm) | 2000x2170x1860 |

| Weight(kg) | |

| Control System | PLC |

| UPH | 330pcs/h |

| Tape-C | Tape-C |

| CT | |

| Working Voltage(AC) | 220V |

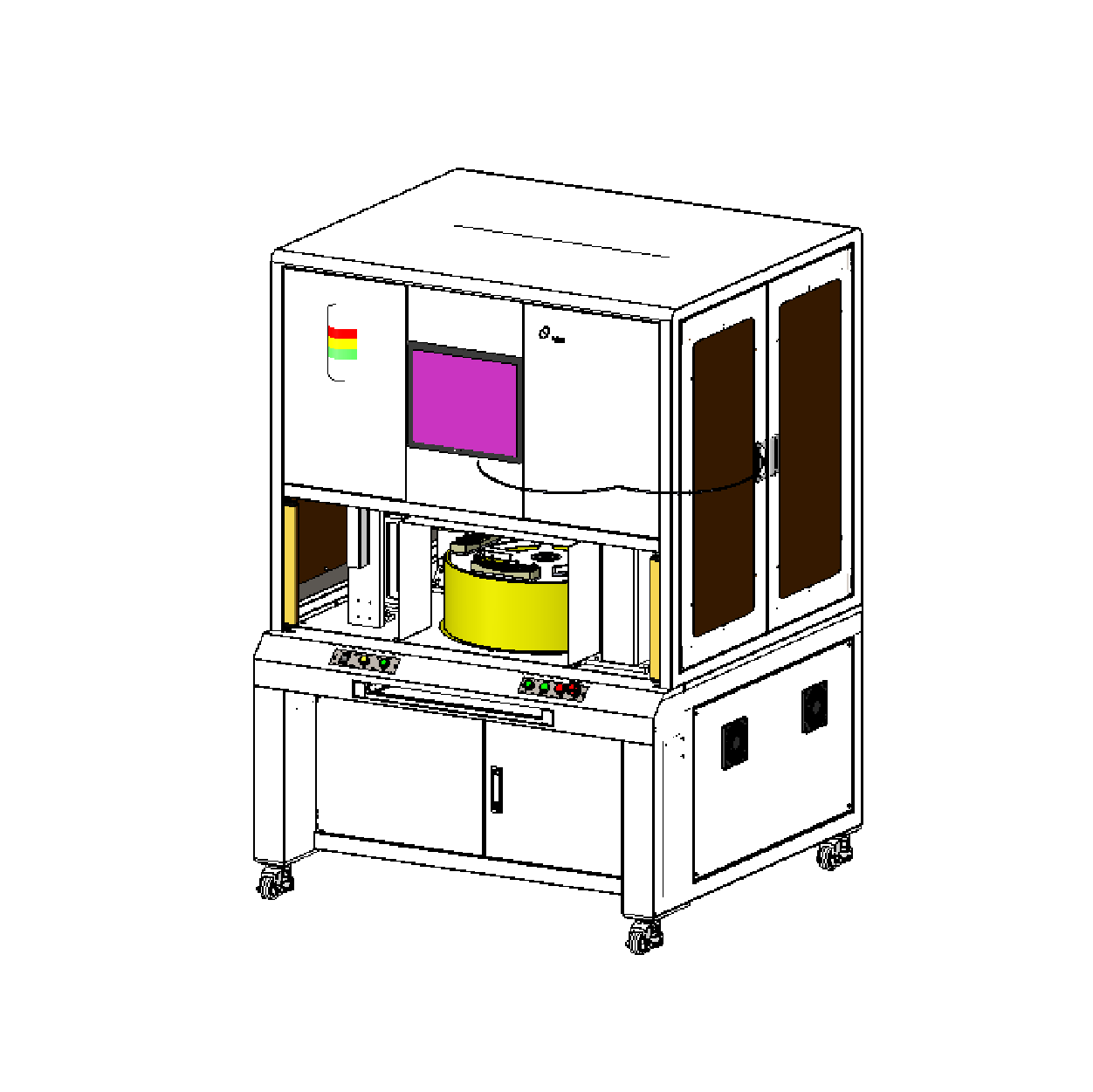

Screw lock pay + attach

The screw lock and Attach function focuses on precisely locking the screws while efficiently attaching the foam material to the specified location. This feature ensures that the components are securely connected and enhances the overall structural strength of the device. At the same time, the attachment of the foam provides additional protection and cushioning, helping to prevent damage to the equipment caused by vibration and shock, thus enhancing the reliability and durability of the product.

Underlying Parameter

| Working Air Pressure(M Pa) | 0.5~0.6 |

| Size(mm) | 1300x1200x1850 |

| Weight(kg) | |

| Control System | PLC |

| UPH | 330pcs/h |

| Yield(%) | |

| CT | |

| Working Voltage(AC) | 220V |

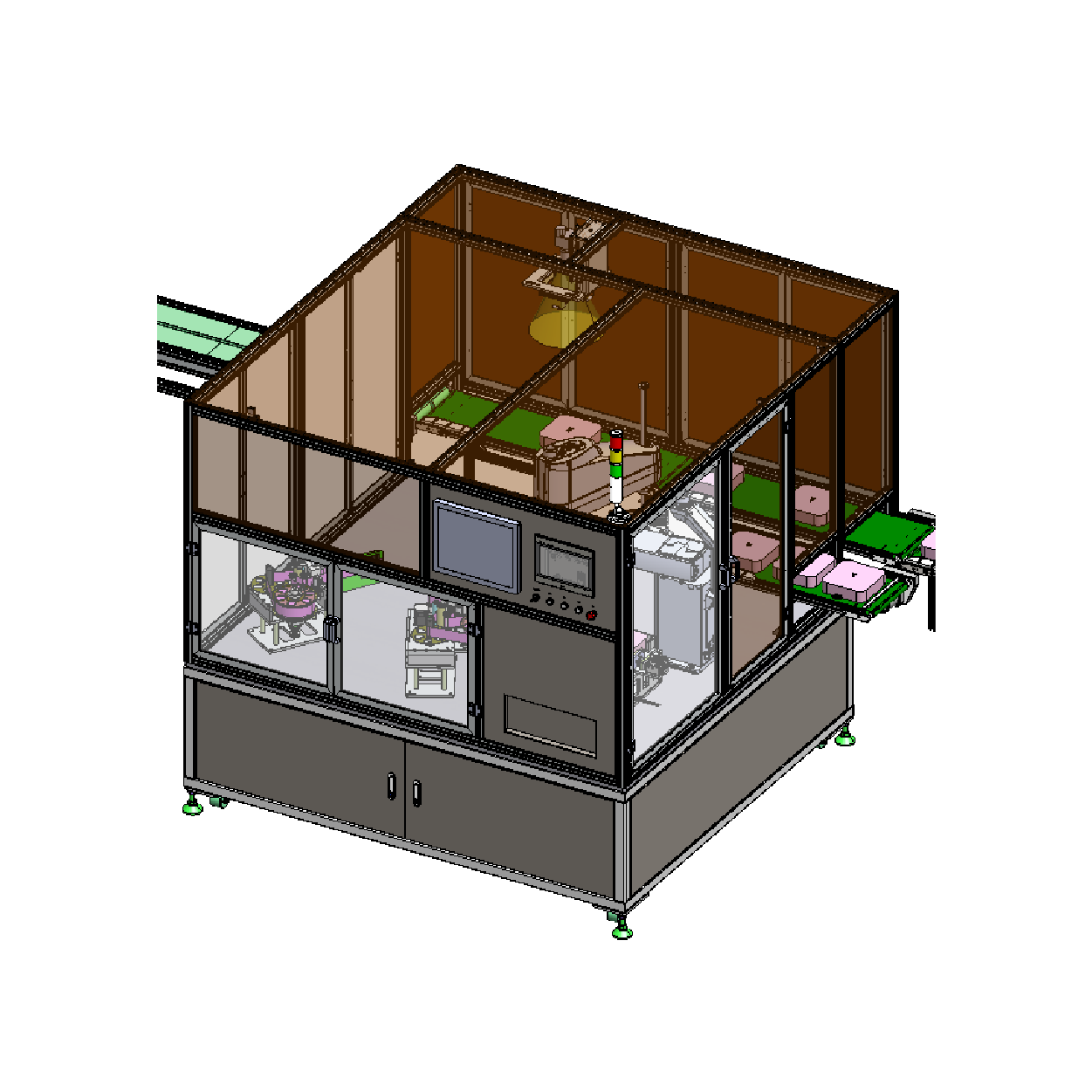

Online detection of diaphragm AOI

AOI online inspection features include automatic feeding and AOI (Automatic Optical Inspection) automatic inspection to ensure the efficiency and accuracy of the diaphragm in the production process. With an automatic feeding system, the diaphragm is quickly and accurately delivered to the inspection area, while AOI technology identifies and detects defects in the quality of the diaphragm in real time, ensuring that each product meets standards. This feature not only improves production efficiency, but also effectively reduces manual intervention and errors, ensuring quality and consistency in the final product.

Underlying Parameter

| Working Air Pressure(M Pa) | 0.5~0.6 |

| Size(mm) | 5735x1900x2000 |

| Weight(kg) | |

| Control System | PLC |

| UPH | 600pcs/h |

| Yield(%) | |

| CT | |

| Working Voltage(AC) | 220V |