Background

In the modern automotive industry, the battery box plays a crucial role as one of the core components of electric and hybrid vehicles. It is not only used to safely store and protect the battery cell, but also to ensure the stability and reliability of the battery under various environmental conditions. With the rapid development of the electric vehicle market, the design and manufacturing of battery boxes are facing increasingly high standards, especially in terms of safety, durability and thermal performance. The material choice of the battery case is also an important factor. Modern battery cases typically use lightweight, high-strength materials, such as aluminum and composite materials, to reduce vehicle weight and improve energy efficiency. In addition, with the development of intelligent technology, battery boxes also need to integrate various sensors and management systems to achieve real-time monitoring and management of battery performance.

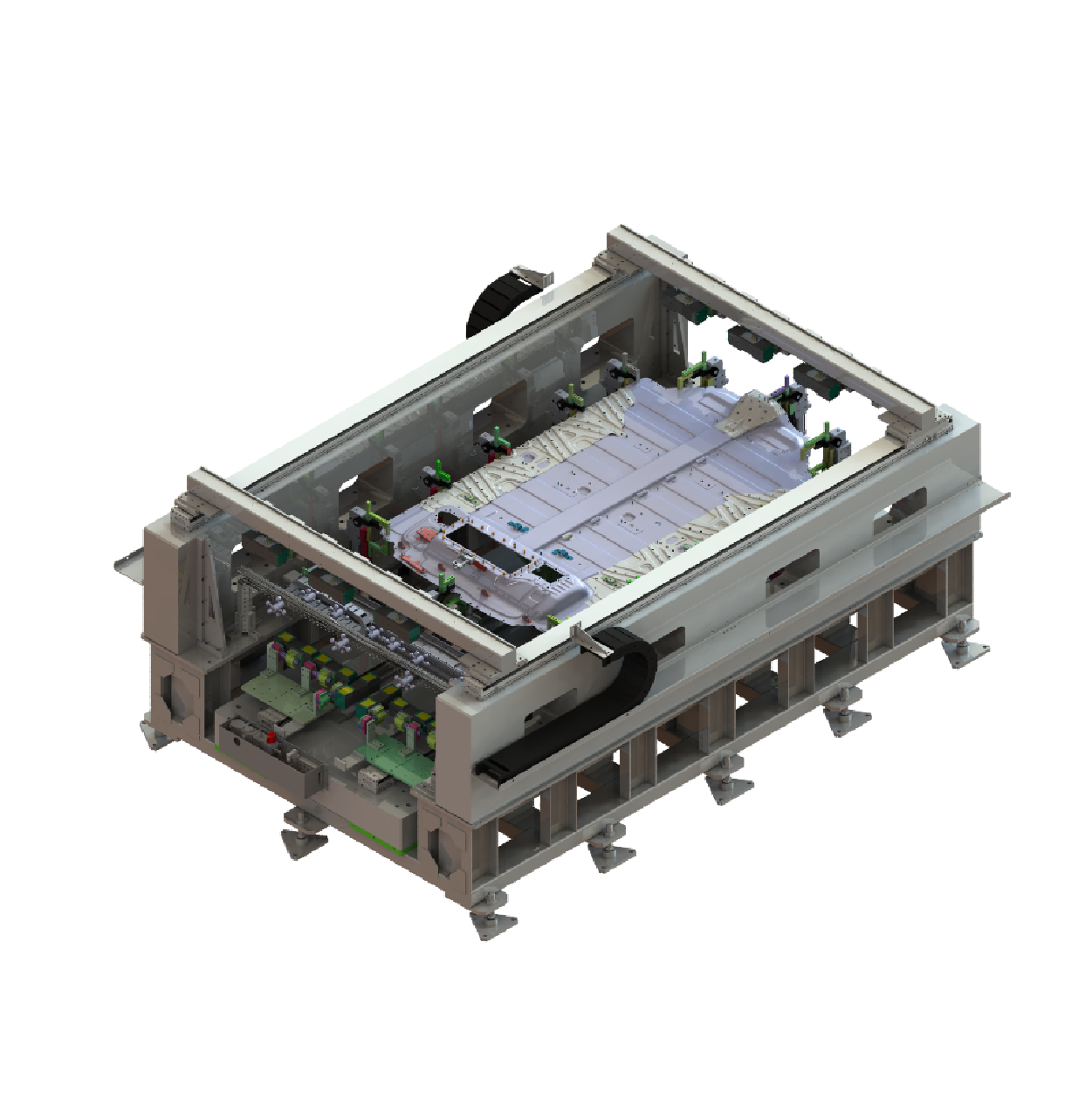

Online detection of battery boxes

The battery box online inspection function mainly includes a number of key steps to ensure product quality and accuracy. First, the system takes a high-precision picture of the size of the battery cover, capturing its individual details for subsequent analysis. Then, through advanced imaging technology, the 3D point cloud data of the product is output to build a three-dimensional model of the battery cover. This model allows for a comprehensive dimensional analysis to help identify any potential deviations or defects. At the same time, the system processes and analyzes the collected data, and generates a detailed inspection report to facilitate quality control and improvement.

Underlying Parameter

| Weight(kg) | 5500 |

| Size(mm) | 5000*3000*5000 |

| UPH | 19 |

| Operation rate (%) | 99% |

| Yield(%) | 99% |

| Control System | PLC |

| Operating voltage (AC) | 220V |

| Working pressure (M Pa) | 0.5 |

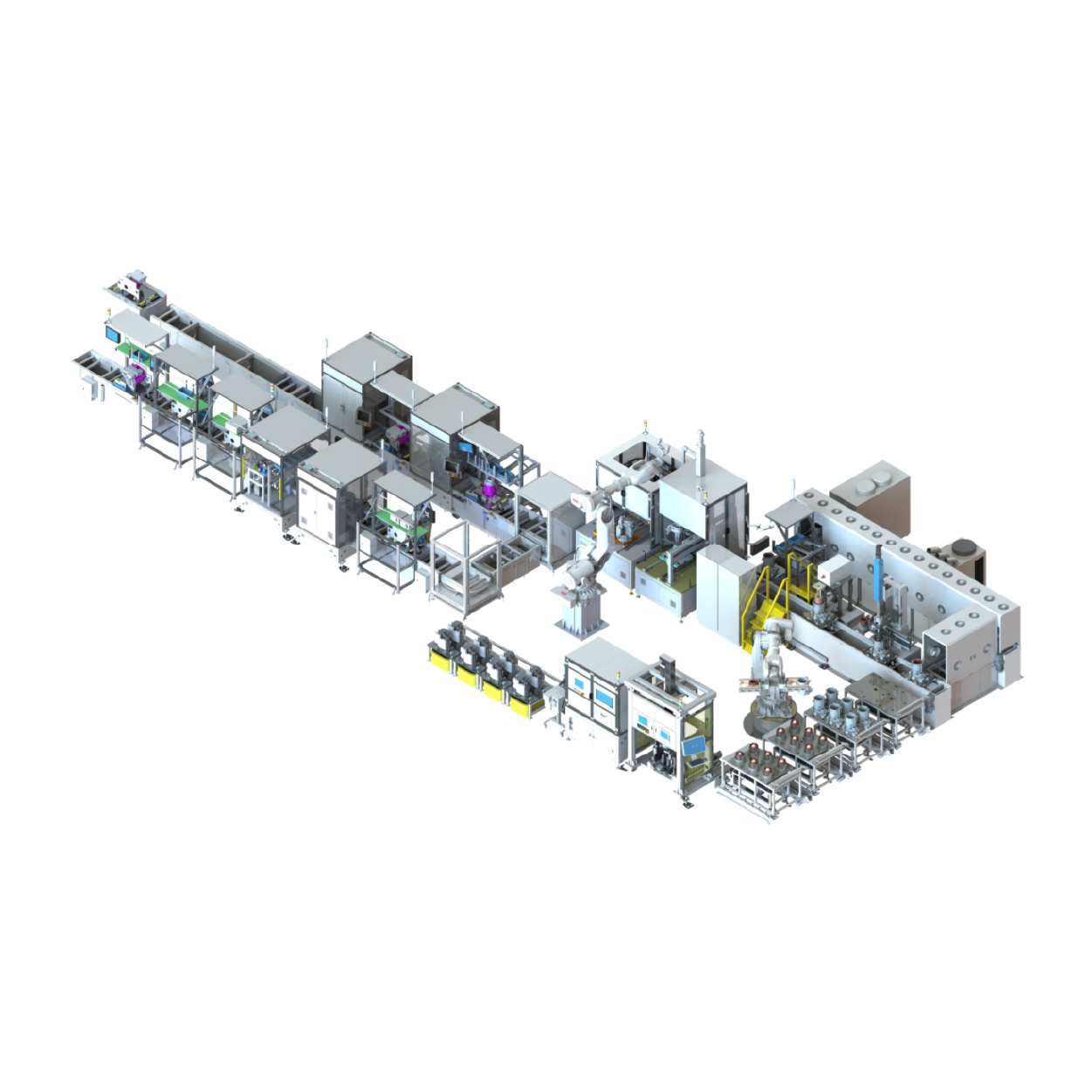

3-in-1 motor assembly

The assembly function of the three-in-one motor mainly includes two important parts: the first is the assembly process of the three-in-one motor, which involves the precise coordination of the motor, the reducer and the driver to ensure that the various components can work together efficiently. Secondly, after the assembly is completed, a comprehensive inspection is carried out to verify the performance and quality of the motor to ensure that it can meet the design standards when running.

Underlying Parameter

| Size(m) | 22X8X2 |

| UPH | 20 |

| Yield(%) | 99% |

| Operation rate (%) | 85% |

| Working pressure (M Pa) | 0.5-0.7 |

Contact Us

For more information about products and solutions, please leave a message.