Background

In the automotive industry, the exterior is not only the visual identity of the vehicle, but also an important part of improving aerodynamic performance and protecting the body. The exterior includes several key components such as body panels, front and rear bumpers, Windows, and lights, and its design and materials directly affect the safety, durability and aesthetics of the vehicle. With increasing consumer demand for vehicle appearance and personalization, the exterior decoration industry is undergoing rapid change. Modern automotive exterior design is increasingly focusing on the application of lightweight and high-performance materials, such as high-strength plastics and aluminum alloys, which not only reduce vehicle weight, but also improve fuel efficiency and vehicle performance. At the same time, the rise of electric and smart cars has also prompted exterior design to take into account new functional requirements, such as battery cooling and sensor integration. These trends put forward higher requirements for the production process and quality standards of exterior decoration.

Automatic label attaching device

The function of automatic label paste equipment covers many important aspects, first of all, it can efficiently and accurately paste the front and rear LOGO, ensure that the brand logo is accurate on the vehicle position, beautiful appearance, and improve the overall image; Second, the device is also responsible for the door opening prompt labels, which not only provide safety tips, but also enhance the user experience and ensure that the information is clearly visible; Finally, the device can automatically attach text and letter labels on the tail to facilitate the identification of vehicle information and other important tips, ensuring that consumers can easily recognize.

Underlying Parameter

| Weight(kg) | 1000 |

| Size(mm) | 7000*5000*1200 |

| UPH | / |

| Operation rate (%) | 99% |

| Yield(%) | 99% |

| Control System | PLC |

| Operating voltage (AC) | 220V |

| Working pressure (M Pa) | 0.5 |

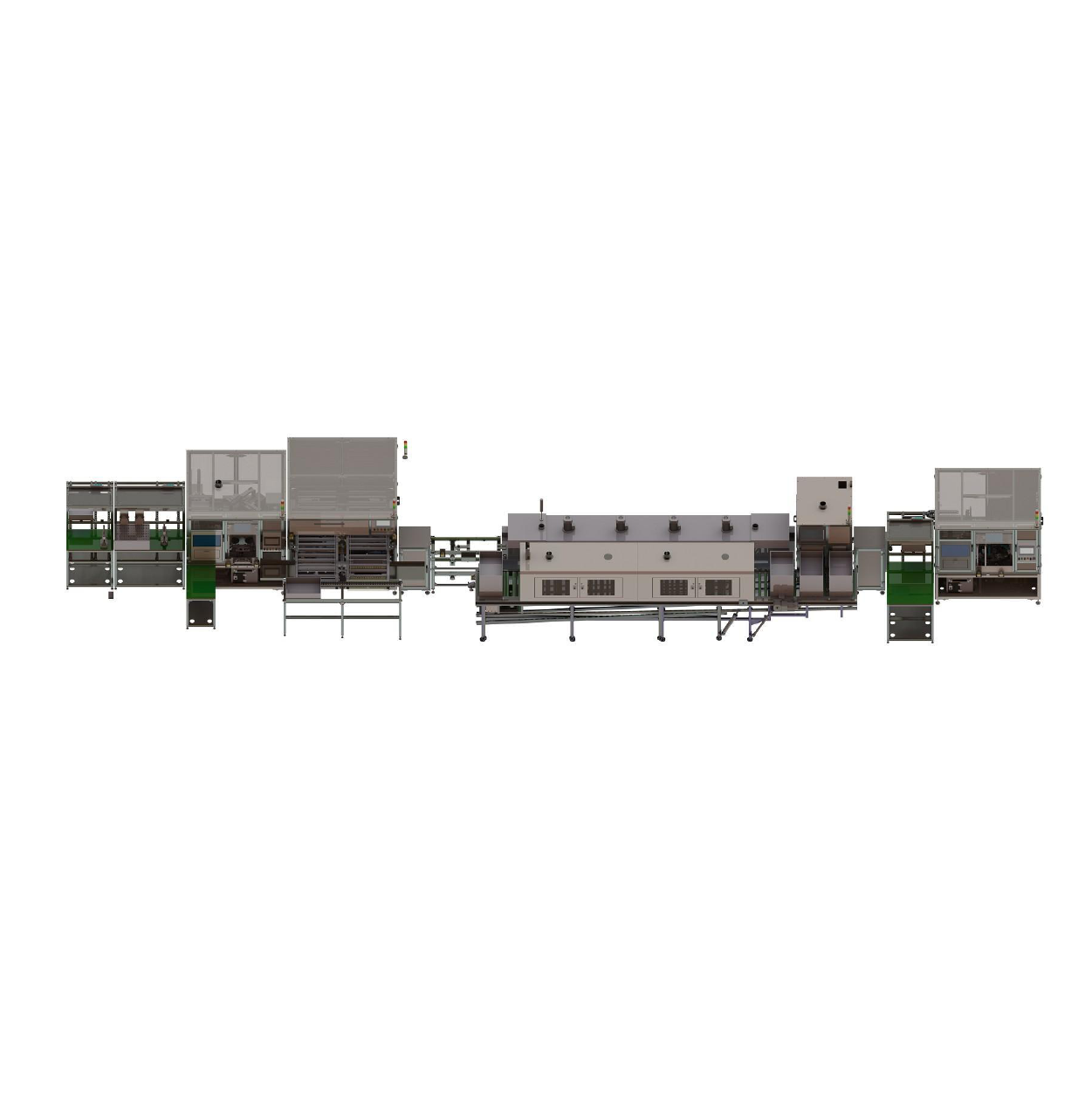

Automotive door handle Potting wire

Automotive door handle Potting wire is a special automation equipment for the production of door handle components, its main functions include the internal electronic components for potting, to achieve sealing protection, effectively prevent the intrusion of moisture, dust and other pollutants, thereby improving the durability and reliability of the components. In addition, potting materials enhance the strength of door handles, improve their impact resistance and vibration resistance, and ensure stability in a variety of driving conditions. For electric door handles, the Potting wire also provides electrical insulation to avoid short circuits and failures. Through the integration of automation technology, the device enables efficient potting, reduces manual intervention, improves production efficiency and product consistency, and thus provides important support for the improvement of overall vehicle performance.

Underlying Parameter

| Size(m) | 17X3X2 |

| UPH | / |

| Yield(%) | / |

| Operation rate (%) | / |

| Working pressure (M Pa) | / |

Contact Us

For more information about products and solutions, please leave a message.