Background

In the automotive manufacturing industry, fasteners play a vital role, responsible for firmly connecting various components together to ensure the safety and stability of the vehicle. Fasteners include bolts, nuts, washers and nails, etc., which play a key role in many aspects of the car’s structure, power system, electronic equipment and interior and exterior trim. With the continuous advancement of automotive technology, especially driven by electric vehicles and intelligent driving systems, the requirements for fasteners are also increasing. Modern automotive design not only focuses on the strength and corrosion resistance of fasteners, but also needs to take into account lightweight and cost control. At the same time, quality control and consistency in the production process have become particularly important to ensure the reliability of fasteners under extreme conditions.

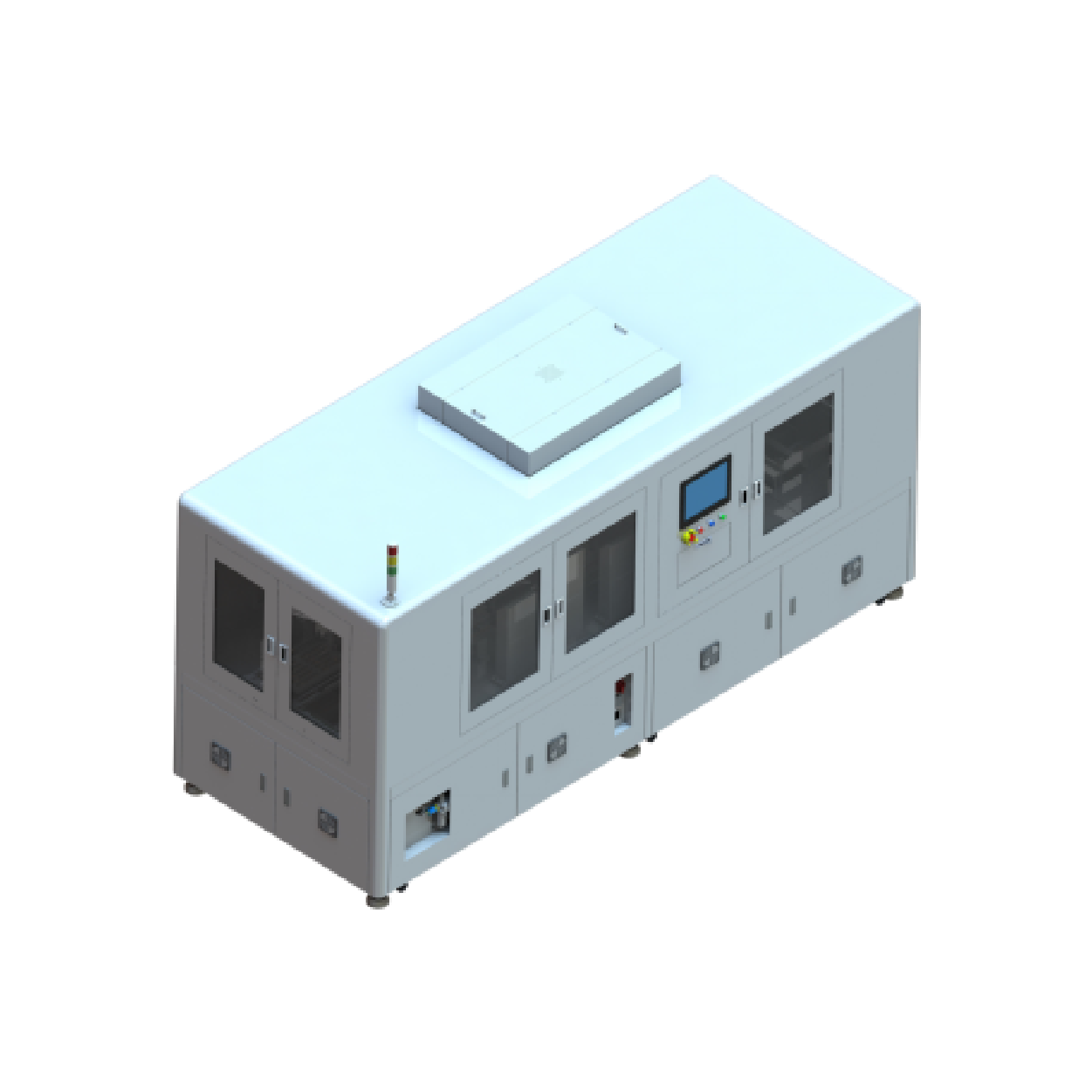

T63 Dimensional measurement

The T63 dimensional measurement function includes several important inspection items to ensure the quality and accuracy of metal parts. First of all, it can detect the PIN width, size, thickness and flatness of the metal parts to ensure that the indicators meet the design standards, thus ensuring the suitability and reliability of the components. Second, the function also focuses on the detection of holes, including the measurement of hole position, hole size, and surface profile, which are critical to ensuring assembly accuracy and functionality.

Underlying Parameter

| Weight(kg) | 3000KG |

| Size(mm) | 2600*1400*2000 |

| UPH | 510 |

| Operation rate (%) | 99% |

| Yield(%) | 99% |

| Control System | PLC |

| Operating voltage (AC) | 220V |

| Working pressure (M Pa) | 0.5 |

Metal parts appearance detection

The appearance detection function of metal parts mainly includes three key aspects: first, it can detect the defects of metal parts, such as scratches, dents, rust or other defects on the surface, to ensure that the appearance quality and performance of the product meet the standard; Secondly, the function accurately measures the position of the hole, evaluates the deviation between the actual hole position and the design hole position, and ensures the accuracy of the component during assembly. Finally, it also checks the size of the hole to ensure that the aperture meets the specified tolerance range, and analyzes the opposite profile to ensure that the geometry of the metal surface is smooth and meets the design requirements.

Underlying Parameter

| Weight(kg) | 3000KG |

| Size(mm) | 3900*1500*1900 |

| UPH | 270 |

| Operation rate (%) | 99% |

| Yield(%) | 99% |

| Control System | PLC |

| Operating voltage (AC) | 220V |

| Working pressure (M Pa) | 0.5 |

Contact Us

For more information about products and solutions, please leave a message.