Background

The field of intelligent driving is in a wave of rapid development, accompanied by the electrification, digitization and intelligent transformation of the automotive industry. Consumer demands for safety, convenience and driving experience are increasing, driving innovation and application of intelligent driving technology. From basic driver assistance systems to comprehensive autonomous driving solutions, intelligent driving technology is reshaping the way we travel. With advances in sensor technology, artificial intelligence and big data analytics, intelligent driving systems are able to process massive amounts of data in real time, identify environmental changes and respond quickly. This enables vehicles not only to navigate autonomously, but also to communicate effectively with other traffic participants, thereby improving driving safety and reducing traffic accidents.

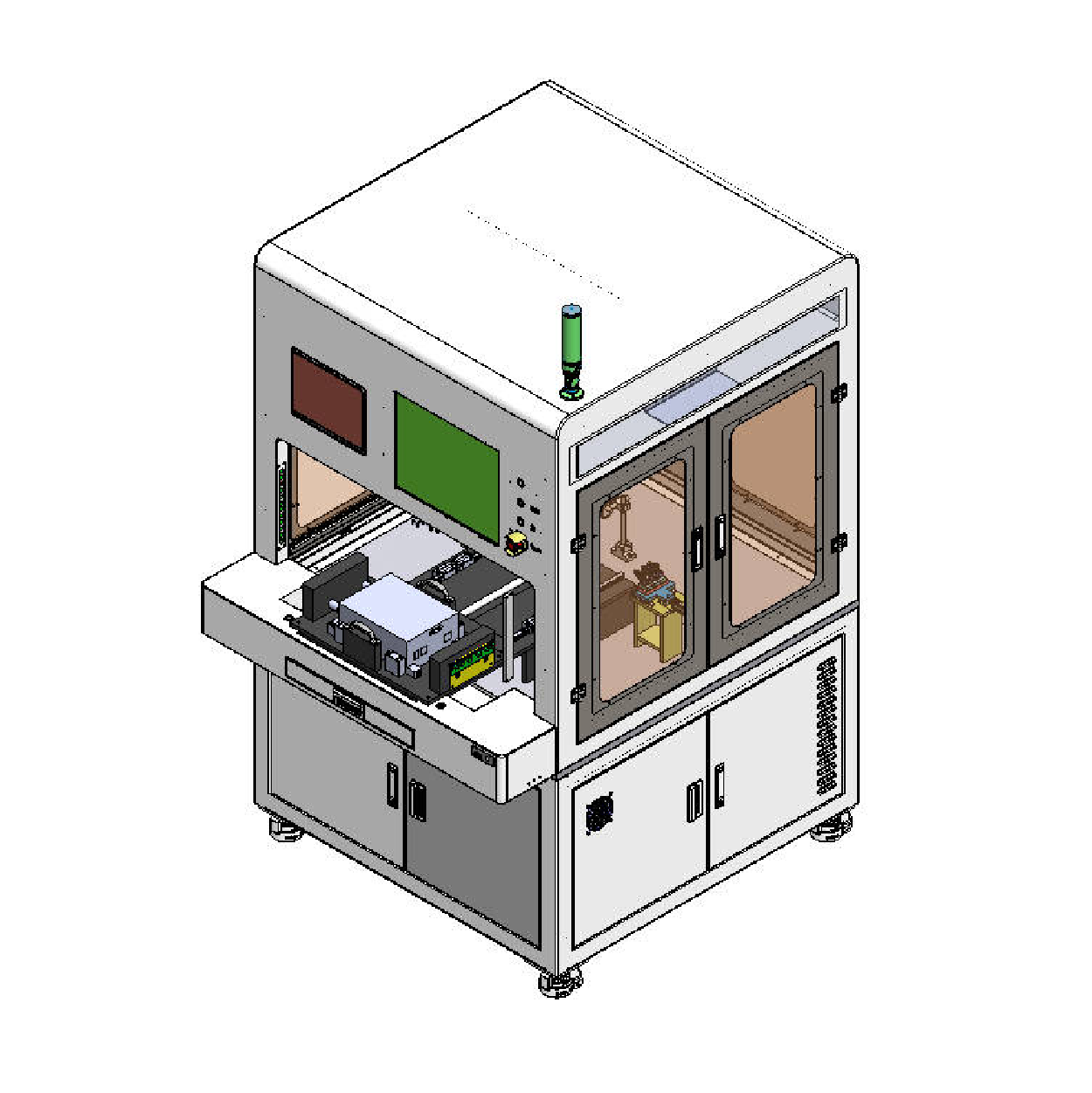

ADAS board level test system

The primary function of the ADAS Board level test system is to perform comprehensive board level testing designed to ensure the performance and reliability of the electronic components of Advanced Driver assistance systems (ADAS). Through an automated test process, the system efficiently evaluates the electrical characteristics of each board, including signal integrity, power consumption and communication protocol compliance. Real-time monitoring and data logging capabilities enable engineers to quickly identify potential problems to optimize designs and improve product quality. In addition, the system supports a variety of test standards and methods to adapt to different ADAS modules, ensuring that each component can operate stably in a variety of environments.

Underlying Parameter

| Weight(kg) | 235 |

| Size(mm) | 1200*800*2110 |

| Software Platform | Malavi platform(Labview) |

| Connection Type | Through probes and interfaces |

| Serial/parallel | Single channel test |

| Electronic Platform | non-standard |

ADAS FCT test system

The ADAS FCT test system provides several key functions to ensure the performance and reliability of intelligent driving systems. It mainly includes power supply voltage test, camera current test, blind area and front and rear view camera input and output test. It also covers CAN-FD communication testing, PPS signal testing, low-side output testing, Gigabit on-board Ethernet testing, software self-test testing, and sleep testing.

Underlying Parameter

| Working Air Pressure(M Pa) | |

| Size(mm) | |

| Control System | |

| UPH | |

| Yield(%) | |

| Operation rate (%) |

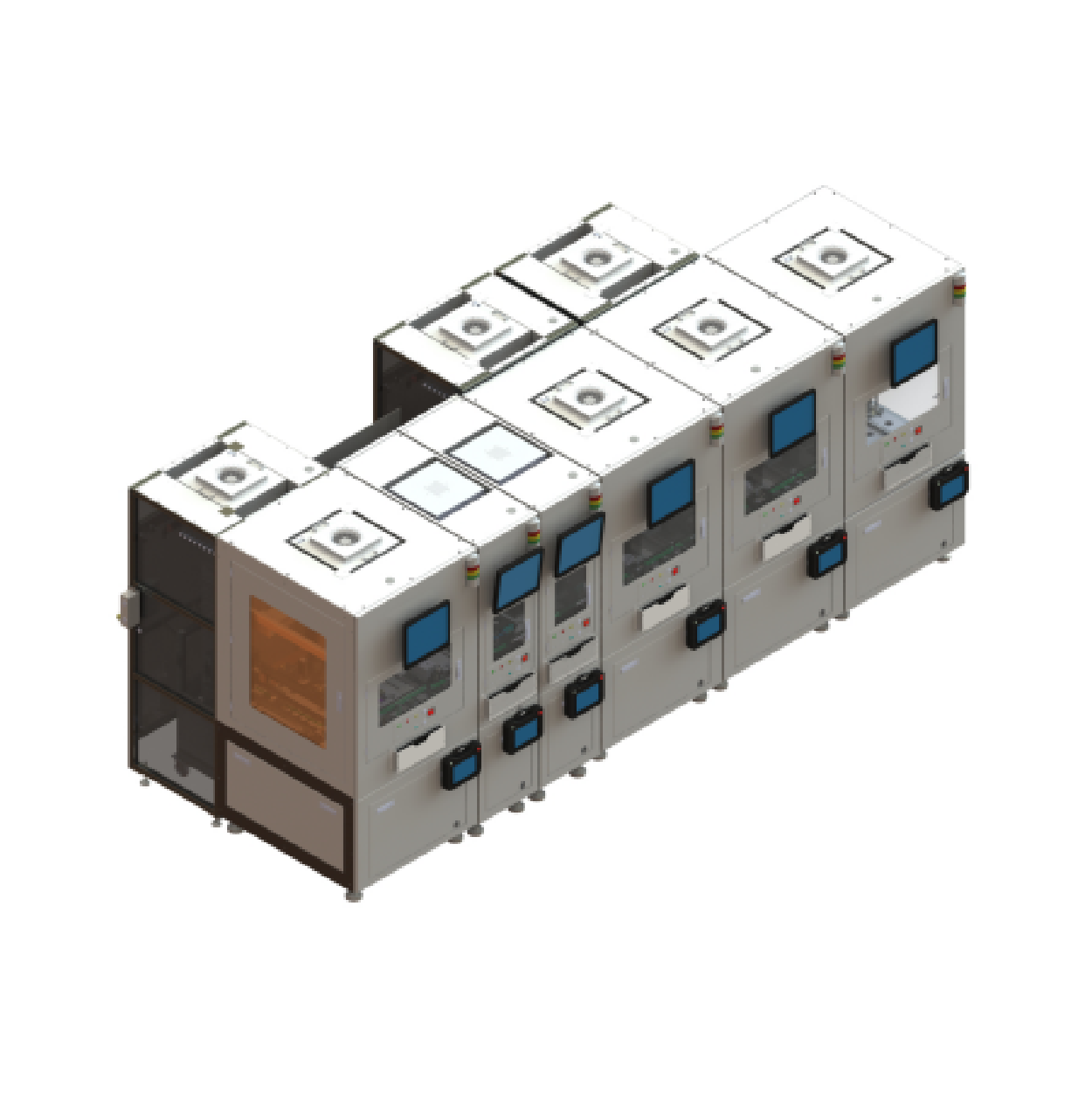

Car camera module automatic assembly line (FOL line)

Automotive Camera Module Automatic Assembly Line (FOL line) is designed to improve production efficiency and product quality, with a number of efficient automation features. First, the automatic feeding system delivers the upper shell, PCBA and lens accurately, ensuring that the components are in place quickly. Secondly, automatic laser technology ensures the consistency of product identification. The Plasma cleaning process removes surface impurities and lays the foundation for subsequent assembly. The active focus system ensures accurate focus of the camera module during assembly, thereby improving image quality. At the same time, the automatic curing process ensures uniform curing of the glue or coating, enhancing product durability. Finally, the automatic plate loading and unloading system efficiently completes the module unloading after assembly, further improving the shipping efficiency.

Underlying Parameter

| Working Air Pressure(M Pa) | 0.4~0.6 |

| Size(mm) | L9000*W2300*H2000 |

| Control System | PLC,IPC,vision |

| UPH | 250 |

| Yield(%) | ≥99.5% |

| Operating voltage (AC) | 220V, 50Hz |

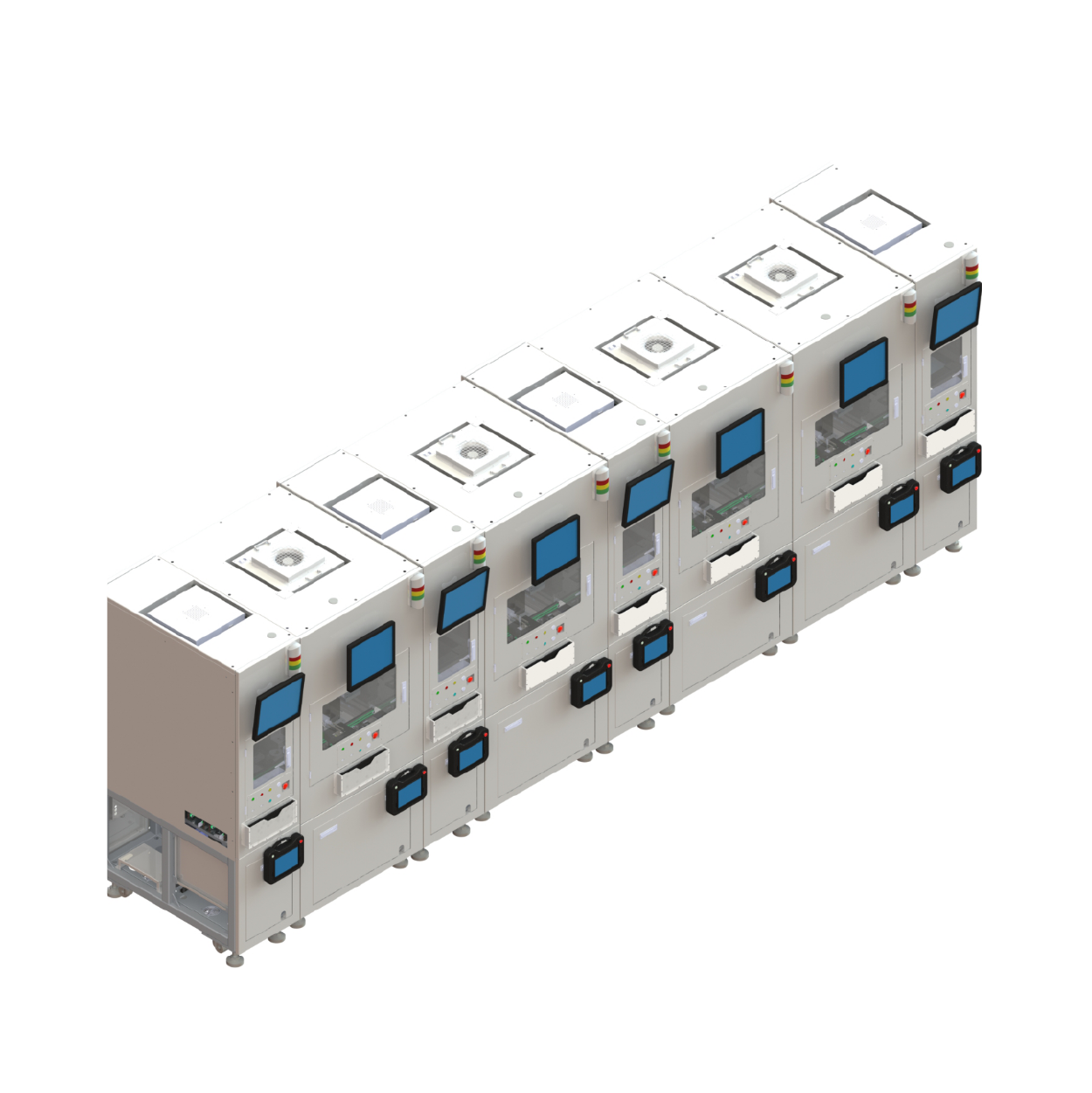

Car camera module Automatic assembly line (EOL line)

Car camera module Automatic assembly line (EOL line) is designed to improve production efficiency and product quality, with a number of automation functions. First, an automatic feeding system ensures that the lower shell and HOLD components are transported quickly and accurately to the assembly location. Secondly, the automatic locking screw function increases the assembly speed and ensures the firmness of the connection. The automatic locking system of the upper and lower shells improves assembly consistency and reliability. The automatic assembly of Fakra connectors ensures precise connection and stability of the interface. Finally, the automatic blanking system efficiently completes the module shipment after assembly, further improving production efficiency.

Underlying Parameter

| Working Air Pressure(M Pa) | 0.4~0.6 |

| Size(mm) | L9200*W2300*H2000 |

| Control System | PLC,IPC,vision |

| UPH | 250 |

| Yield(%) | ≥99.5% |

| Operating voltage (AC) | 220V, 50Hz |

| Working Voltage(AC) |

Contact Us

For more information about products and solutions, please leave a message.